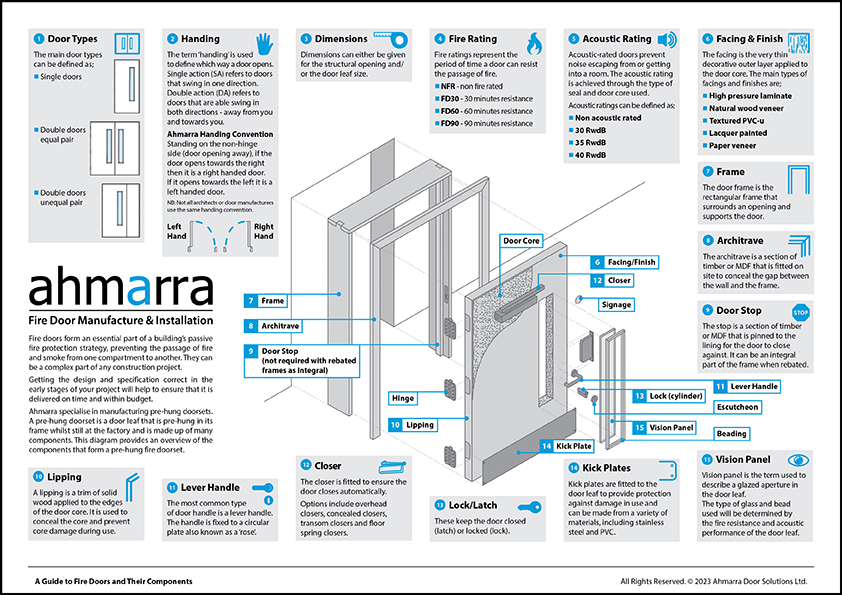

Fire doors form an essential part of a building’s passive fire protection strategy, preventing the passage of fire and smoke from one compartment to another. They can be a complex part of any construction project. Getting the design and specification correct in the early stages of your project will help to ensure that it is delivered on time and within budget. This guide provides an overview of the terminology, components and key factors to consider when specifying fire doors – from certification and performance ratings to door types and ironmongery.

Third Party Certification

Third-party certification means that the manufacturer/installer has undergone a rigorous audit and testing process conducted by an impartial, independent specialist body. This involves having documented product specifications, installation instructions and strictly controlled factory production processes.

Specifying third-party certified fire doors is the most effective way to ensure that the critical safety standards, required under Approved Document B of the Building Regulations, are achieved.

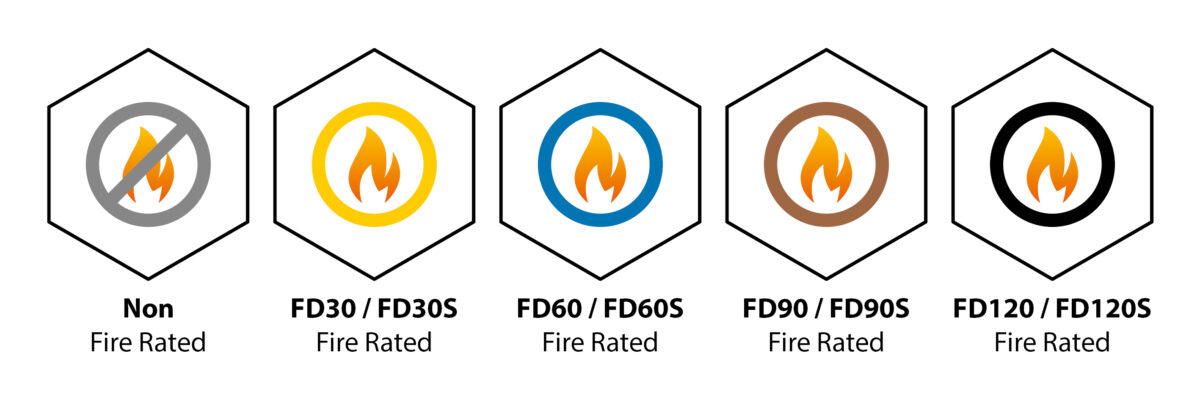

Fire Ratings

Fire ratings represent the period of time a door is furnace tested to and anticipated to perform in the event of a fire.

Fire door ratings can be defined as;

- NFR Non fire rated

- FD30 30 minutes fire resistance

- FD60 60 minutes fire resistance

- FD90 90 minutes fire resistance

- FD120 120 minutes fire resistance

An ‘S’ suffix (e.g. FD30S) denotes that the door is both a fire and smoke controlled door.

The fire rating should be determined by the building’s fire safety strategy

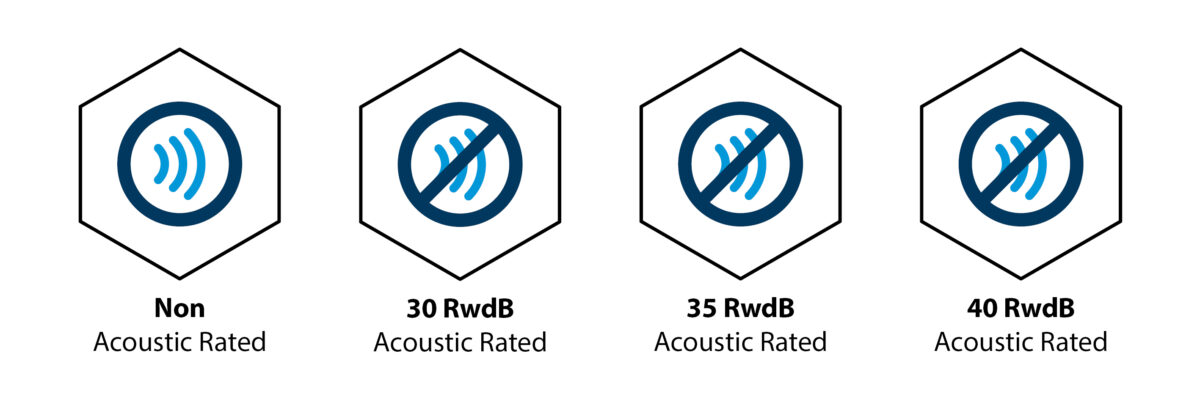

Acoustic Ratings

Acoustic-rated doors prevent sound escaping from or getting into a room. The acoustic rating is achieved through the type of seal and door core used.

Acoustic ratings can be defined as;

- Non acoustic rated

- 30 RwdB

- 35 RwdB

- 40 RwdB

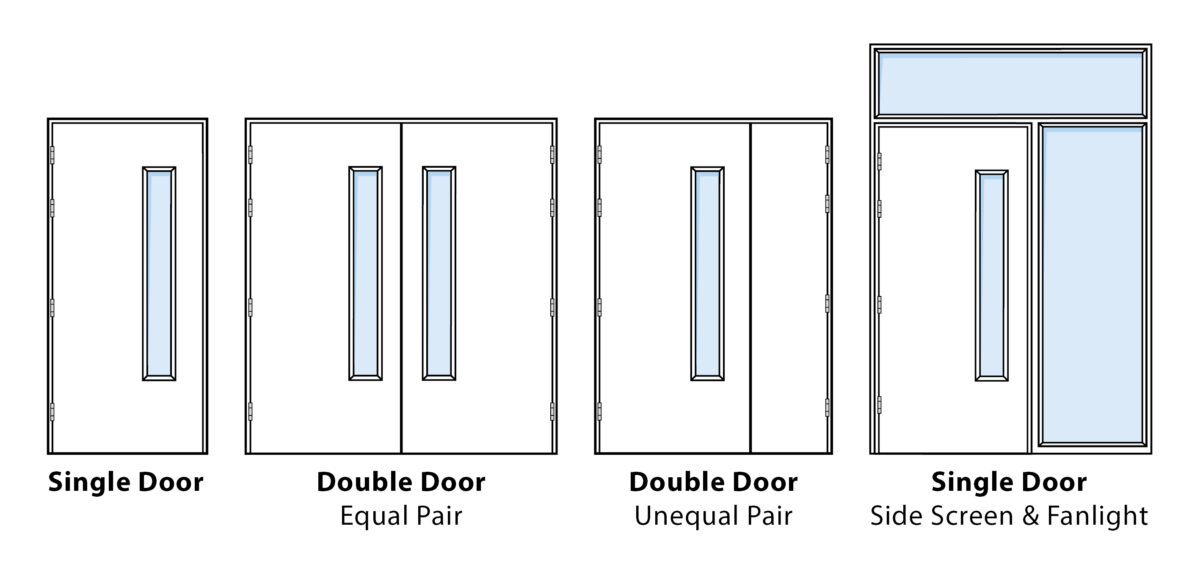

Door Types

The main door types can be defined as;

- Single Door

- Double Doors – Equal Pair

A pair of doors, with door leaves of equal width, hung from a single frame - Double Doors – Unequal Pair

A pair of doors, with one of the door leaves (usually the active leaf) wider than the other leaf, hung from a single frame

These door types can also be supplied with side screens and/or fanlights.

Handing

The term ‘handing’ is used to define which way a door opens.

Single action (SA) refers to hinged or pivoted doors that swing in one direction only.

Double action (DA) refers to hinged or pivoted doors that are able swing in both directions – away from you and towards you.

Ahmarra Handing Convention means that when standing on the non-hinge side (door opening away), if the door opens towards the right then it is a right handed door. If it opens towards the left it is a left handed door.

Dimensions

The dimensions of the materials we use, and of the products we produce, are a critical part of our business. They are measured at each stage of the process to ensure accuracy.

Dimensions can either be given for the structural opening and/or the door leaf size.

Door Leaf

The door leaf is the main component of, and the hinged, pivoted or sliding part, of the doorset or door assembly.

Frames

The door frame is the rectangular fixed frame surrounding the structural opening from which the door(s) are hung.

It is usually made from engineered softwood, engineered hardwood or solid timber.

Architraves

The architrave is a section of timber or mdf that is fitted on site to conceal the gap between the wall and the frame.

Door Stops

The stop is a section of timber or mdf that is pinned to the lining for the door to close against. It can be an integral part of the frame when rebated.

The door stop’s purpose is to limit the swing of a single action door.

Vision Panels

Some fire doors have a vision panel (glazed aperture) fitted within the door leaf. Vision panels are encased by glazing bead. The type of glass and bead used will be determined by the fire resistance and acoustic performance of the door leaf. Vision panels are an important safety feature, allowing building occupants to see what is on the other side of the door, which is vital in preventing injury resulting from collision with opening doors.

There are three main types of fire resisting glass;

Integrity (E)

E offers the base level of fire performance and is also the minimum requirement stated by the UK Building Regulations. It provides effective protection against fire and smoke, but does not prevent the transmission of heat.

Integrity & Radiation (EW)

EW represents an increased level of protection. Fire glass that achieves the EW classification offers the same level of protection against fire and smoke as E, as well as a reduction in the amount of radiant heat transmitted to the protected side. Specifically, EW keeps radiant heat below 15kW/m2.

Integrity & Insulation (EI)

The EI classification offers the highest level of protection. As well as providing a robust barrier against fire and smoke, EI also offers a significant reduction in the amount of heat transferred through the glass, keeping the average temperature of the unexposed side below 140°C. This means that if there is a raging fire on one side of the glass, with temperatures above 800°C, building users on the unexposed side remain protected from the heat and can make an escape.

Please note: While the type of protection offered is determined by the product’s classification, the length of time for which this protection can be maintained will vary from 30 minutes up to 180 minutes.

Intumescent Seals

Intumescent seals are used to restrict the flow of heat, flames and hot gases. The seals work by expanding when subjected to elevated heat during a fire, filling any gaps or voids, such as that between the door and frame.

Smoke Seals

Smoke seals are used to restrict the flow of smoke and hot gases only. They are fitted around the door leaf edge or frame reveal, and can be combined with or separate from the intumescent seals.

Ironmongery

Ironmongery or door hardware are the doorset components, that are usually made from metal, and are fixed to a door or frame to enable the operating and securing of the door leaf. Examples of architectural ironmongery include; locks, latches, closers, protection plates, hinges, pivots, handles, signage, escutcheons, flush bolts etc.

Ironmongery for fire doors must be fully compatible, Certifire approved and CE marked.

Locks and Latches

Locks and latches are critical in keeping the door closed in the event of a fire and preventing warping of the door.

Locks secure the door and are operated by a key or other device, whilst latches hold the door in a closed position when shut.

Closers

A door closer is a mechanism that connects the door to its frame, enabling it to automatically return to a fully closed position. It is mandatory that fire doors are kept closed in order to perform in the event of a fire. Closers can also help to control noise, maintain room temperature and provide privacy.

Protection Plates

The plates are fitted to the door leaf to provide protection against damage in use and can be made from a variety of materials including stainless steel and PVC.

Protection plates, such as push plates, kick plates, mid-rail plates and half height plates, make doors more resistant to impact and prolong their longevity.

Lippings

A lipping is a trim of solid wood applied to the edges of the door core. It is used to conceal the core and prevent core damage during use.

Lippings are available as exposed, concealed or semi-concealed design options.

Facings & Finishes

The facing is the very thin decorative outer layer applied to the door core.

A wide range of decorative facings and finishes are available to complement the building’s interior design scheme.

The main types of facings and finishes are;

- High pressure laminate

- Natural wood and stained veneer

- Textured PVC-u

- Lacquer painted

- Primed eco-paper veneer – ready for on-site painting

To download our Fire Doors and Components Diagram, click here.