Ahmarra’s Q-Mark certified Healthcare Door Range is available with anti-bacterial, impact resistant PVC-u or high pressure laminate facings, that support a modern hospital’s infection control strategy. They are also available with wood veneers.

PVC-U DOOR FACINGS

The 2mm impact resistant PVC-u range is available in 15 standard colours in a textured finish, offering a choice of contrasting, co-ordinating and harmonising solutions. The sheets can be applied to doors, door edges and glazing beads, kick plates, frames, stops and architrave.

These hygienic PVC-U door facings include an anti-bacterial additive that is integrated within the sheet material construction, causing 99.9% of bacteria to die within 24 hours.

More colour options are available on request, as well as volatile organic compounds (VOC) free options at a premium.

Polar White

RAL 9003 • LRV 84.02

Ivory

RAL 1013 • LRV 73.85

Pale Grey

RAL 7044 • LRV 51.38

Snow White

RAL 9001 • LRV 73.07

Sand

RAL 1014 • LRV 60.08

Pale Green

RAL 6034 • LRV 37.32

Slate Grey

RAL 7011 • LRV 13.09

Poseidon Blue

RAL 5012 • LRV 27.13

Olive Green

LRV 18.34

Pale Blue

RAL 5024 • LRV 31.03

Twilight Blue

RAL 5003 • LRV 8.25

Steel Grey

RAL 7038 • LRV 39.59

Storm Grey

RAL 7037 • LRV 21.66

Misty Grey

RAL 7046 • LRV 12.55

Light Beige

LRV 44.85

HIGH PRESSURE LAMINATE DOOR FACINGS

The high pressure laminate range is available in a range of colours. These laminates are FSC® certified and VOC free Greenguard certified as standard.

These hygienic high pressure laminate door facings include an anti-bacterial additive that is integrated within the sheet material construction, causing 99.9% of bacteria to die within 24 hours.

For the full range of Polyrey door laminate finishes, click here.

Laminates from other suppliers such as Formica are also available.

Blanc Artic

B117 FA • LRV 86.0

Orgeat

0111 FA • LRV 79.0

Blanco Especial

030 • LRV 83.0

Gris Tourerelle

G029 FA • LRV 55.0

Gris Dauphin

G044 • LRV 55.0

Gris Perle

G003 FA • LRV 40.0

Beige Nature

B116 FA • LRV 51.0

Gris Cendré

GO75 FA • LRV 32.0

Gris Acier

GO76 • LRV 15.0

Gris Orage

G059 FA • LRV 9.0

Bleu Oslo

B048 FA • LRV 52.0

Vert de Gris

V106 FA • LRV 40.0

Cèdre Bleu

C118 FA • LRV 27.0

Bleu Note

B198 FA • LRV 18.0

Bleu Velvet

B196 FA • LRV 13.0

WOOD VENEER DOOR FACINGS

Wood veneers, as opposed to solid wood, provide a perfect uniform finish – free from knots, splits and staining. We only use wood veneers that are legally logged from responsibly managed forests and certified by the FSC® (Forest Stewardship Council®).

Our most popular wood veneer door facings are below. For more options, view our ‘Decorative Facings and Finishes’ brochure.

American Cherry

Crown Cut • Average LRV 23.8

American Cherry

Quarter Cut • Average LRV 23.4

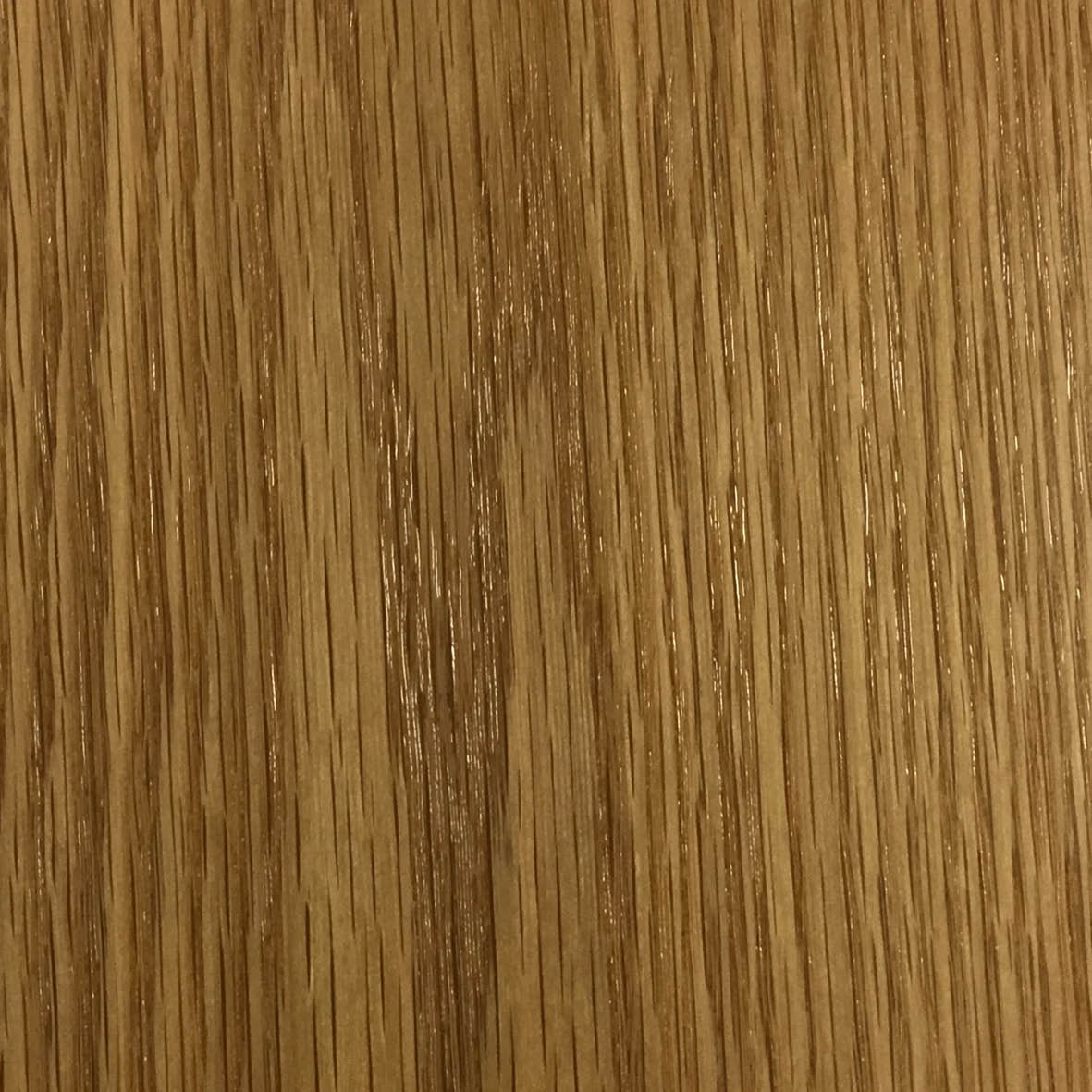

American White Oak

Crown Cut • Average LRV 31.8

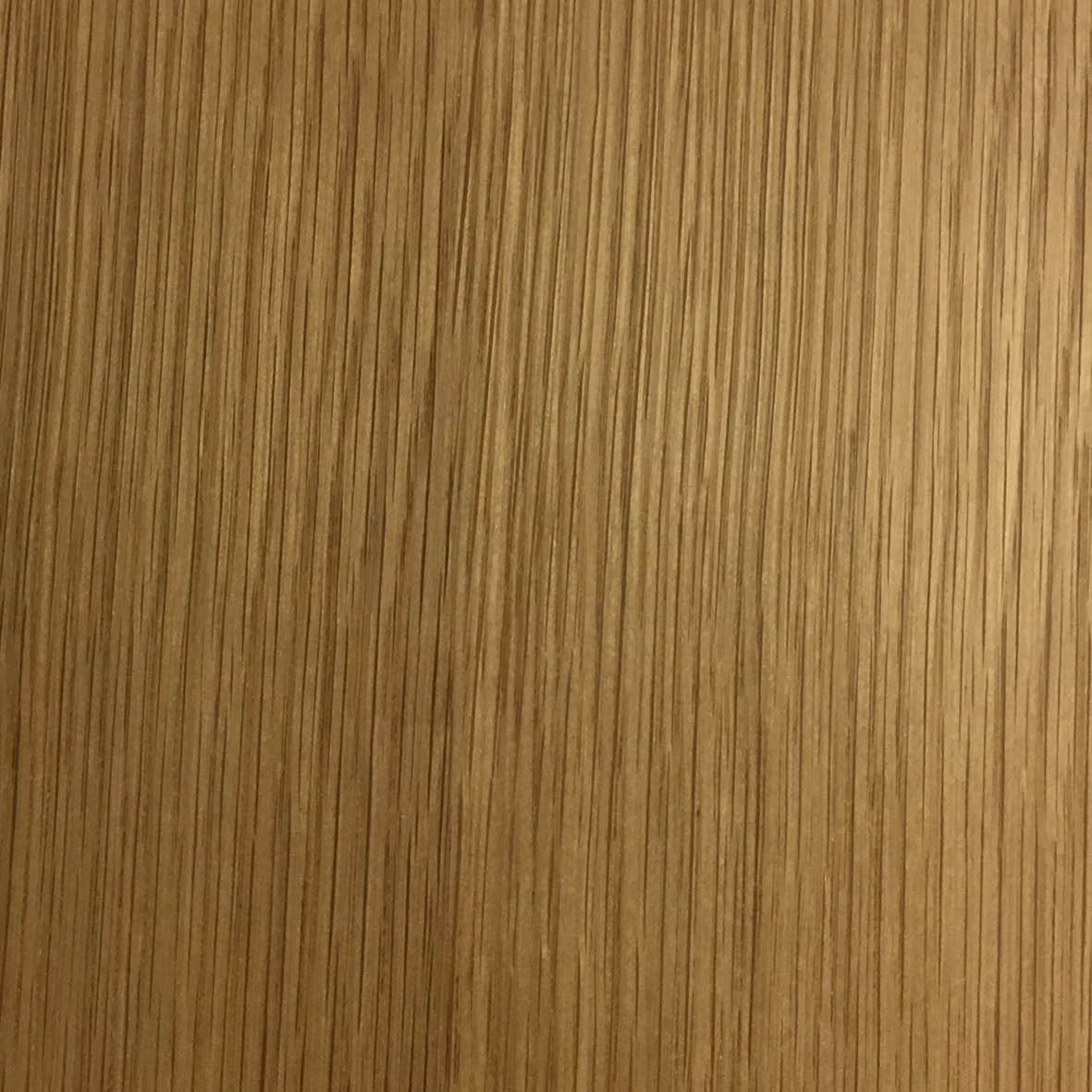

American White Oak

Quarter Cut • Average LRV 35.4

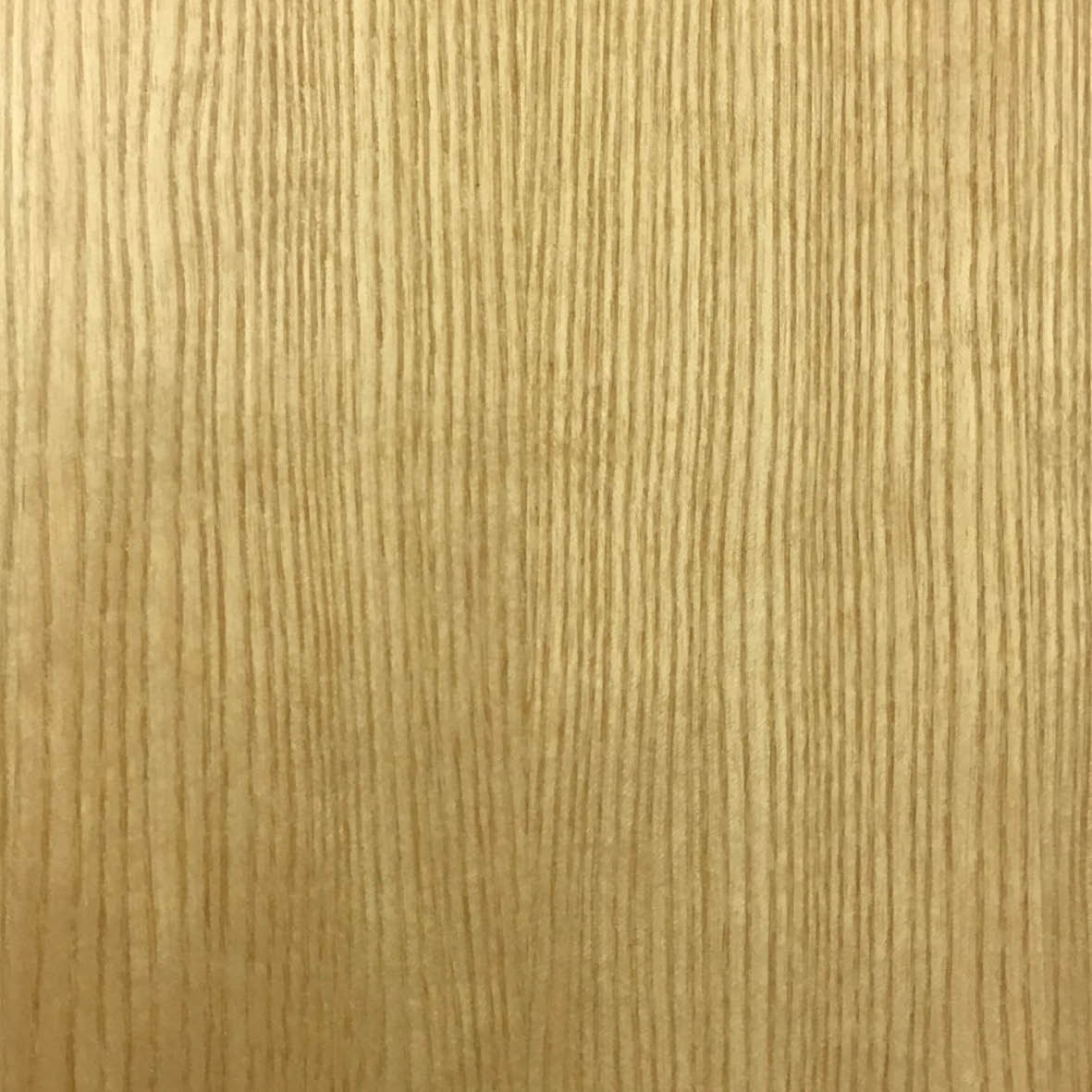

Ash

Crown Cut • Average LRV 51.5

Ash

Quarter Cut • Average LRV 55.9

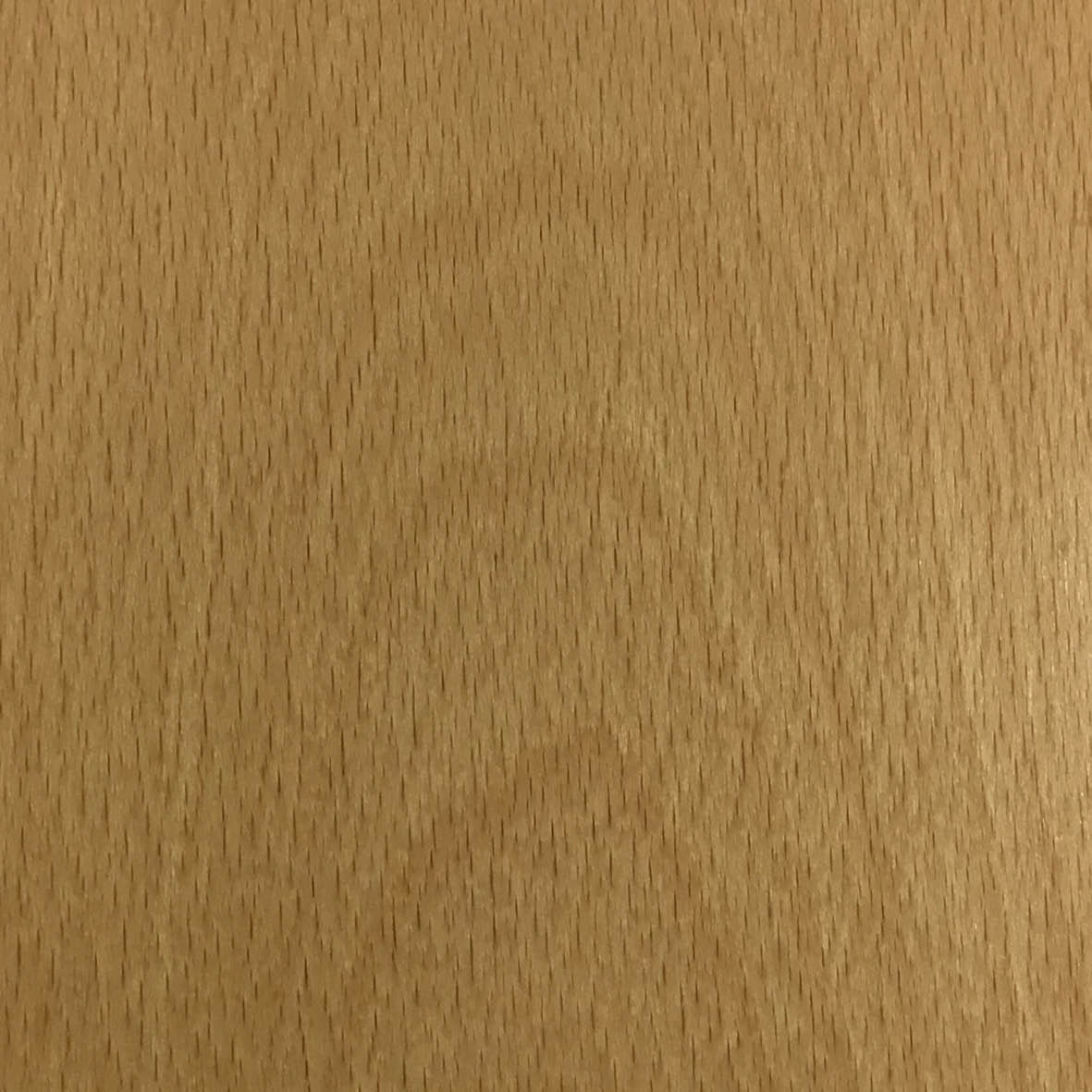

Steamed Beech

Crown Cut • Average LRV 35.8

Steamed Beech

Quarter Cut • Average LRV 36.0

Maple

Crown Cut • Average LRV 54.3

Maple

Quarter Cut • Average LRV 57.7

American Black Walnut

Crown Cut • Average LRV 14.7

American Black Walnut

Quarter Cut • Average LRV 16.9

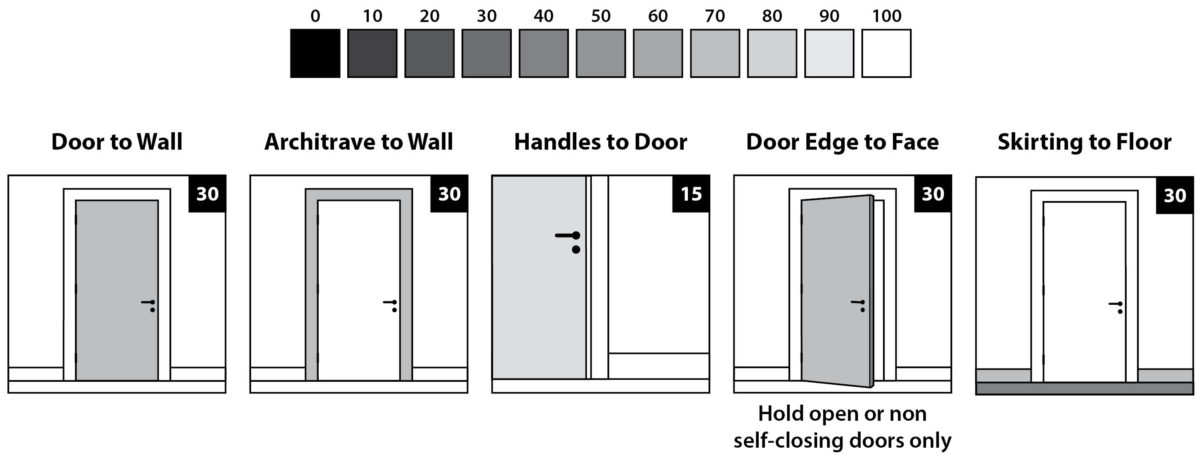

LIGHT REFLECTANCE VALUES (LRV)

What are Light Reflectance Values (LRV)?

Light Reflectance Values are a universal scale that measures the amount of visible and usable light that is reflected from a surface when illuminated by a light source. It is used in architecture and interior design to determine how much light a colour reflects or absorbs. LRV is measured on a scale of 0 being completely absorbing black that reflects no light, to 100 being completely reflecting white that reflects all light. Because the reflectance value is a proportion of the light reflected off the surface, rather than the amount of light that falls on it, typically the brightest whites have an LRV of 85 points and the darkest blacks have an LRV of 5 points.

Why are Light Reflectance Values important?

The Equality Act 2010 requires that all new and refurbished public buildings offer equal access to all regardless of disability, age or gender, ensuring safe entry, exit and passage through the building.

The British Standards’ code of practice (BS 8300-2:2018) states that in order to meet the access needs of disabled people, in this case those that are visually impaired, there must be adequate visual contrast between building surfaces and their surrounding areas. Only 5% of people that are registered as blind can’t see anything at all, most have some colour vision and perception of light & shade.

What is the required contrast between Light Reflectance Values?

The standards recommend an LRV contrast of at least 30 points, with 20 points being acceptable if the illuminance on the surfaces is 200 lux or more. If door opening furniture projects beyond the face of the door or creates an enhanced differentiation in shade, the LRV contrast must be a minimum of 15 points.

For further details, please refer to Building Regulations Approved Document Part M – Volume 2 and BS 8300-2:2018, Annex B.

How do Light Reflectance Values (LRV) relate to specifying doors?

When specifying doors, it is important to consider the LRV contrast between the door facing and ironmongery, in order to comply with BS 8300:2018 requirements.

The figures on the samples above give an indication of the Light Reflectance Values. They are to be used as an approximate guide, as precise finishes and environments can vary.